Roll Vacuum Packaging Machine

Model: DZ-1000QF

Description

Roll vacuum packaging machine could be set one or two sealing bars according to different size packing item, which improve the packing efficiency.The vacuum chamber is driven by pneumatic component. Compared to electrical machinery driving, the pneumatic component is operating with low failure rate and easier to maintain.

Application of Vacuum Sealing Machinery

Roll vacuum packaging machine is applicable to vacuum packaging of food, material, electrical product and chemical product.

Features of Vacuum Sealing Machinery

1. Equipped with OMRON PLC programmable control system, the data setting and motion control are more accurate and the performance is more reliable so the operation is easier.2. The turnover stainless steel vacuum cover is sturdy and durable to guarantee long-term trouble-free continuous operation and provide more conveniences for routine maintenance.

3. The roll vacuum packaging machine is equipped with high-power efficient vacuum pump to make the packing bag to obtain a higher degree of vacuum in a short time, which improves the work efficiency.

4. The conveyor belt is rugged, antibacterial with high density. Its elastic geometric is stable and easy to clean.

5. Variable adjustment of the working angle can be made as required in 0 to 15 degree for packing of product with liquid.

6. High quality pneumatic elements ensure the quality of vacuum sealing machinery to be stable and reliable.

7. The main structure of the roll vacuum packaging machine is made of 304 Stainless Steel to ensure its elegant appearance as well as the anticorrosion in harsh caustic environment.

8. The "V” shaped chamber lid gasket is made of high-density material, which ensures sealing performance.

9. Service life of sealing tape can be extended by using compressed and wearing resistance material, and change frequency can be also reduced.

10. The length of bar is 1000 mm, which could be used to pack many packages at the same time in order to improve the working efficiency and met the mass production packing requirement.

11. The roll vacuum packaging machine is equipped with heavy-duty mobile caster wheels and sturdy feet with good loading capacity and stability. This makes it easier for users to move the position.

12. The conveying part uses antibacterial belt and one-touch release mechanism. The inside (like console) and back of the belt is cleaned to guarantee the health and safety of all operating processes.

13. The vacuum sealing machinery is equipped with emergency stop switch. In case of accident, the operator can press the emergency stop switch at any time to terminate the ongoing work program.

14. Equipped with OMRON PLC programmable control system, the data setting and motion control are more accurate and the performance is more reliable so the operation is easier.

15. The control cabinet is set in the upper part of the machine. Equipped with microcomputer system control, it is easy to operate as well as convenient for maintain and replacement of wearing parts.

Parameter

| Model | DZ-1000 QF Roll Vacuum Packaging Machine |

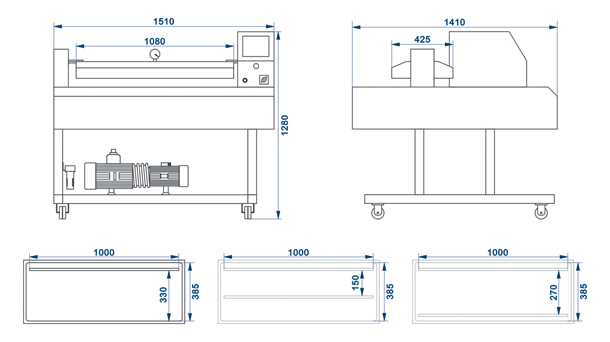

| Machine Dimensions(mm) | 1510 × 1410 × 1280 |

| Chamber Dimensions(mm) | 420 × 1085 × 75 |

| Sealer Dimensions(mm) | 1000 × 8 × 2 |

| Vacuum Pump(m³/h) | 100/200 |

| Power Consumption(kW) | 2.2 |

| Electrical Requirement(v/Hz) | 380/50 |

| Production Cycle(times/min) | 2 to 3 |

| Net Weight(kg) |

447 |

| Shipping Dimensions(mm) | 1530 × 1640 × 1480 |

Sketch Map

Related Products

-

- DL-410KADL-410KA tray sealing equipment is applicable to fresh-keeping packaging of all types of boxed fresh, cooked food, such as cool fresh meat, cooked meat products, fast food, pastry, rice noodle,

-

- DZ-390TDZ-390/T table top vacuum packaging machine is widely applied in vacuum packaging of various food, medicine, electrical product and chemical product.